Surface Preparation

Any peeling or flaking paint on a previously painted surface must be removed before recoating. All cracks and pits in the surface must first be filled with any common paintable crack filling material. Asphalt surfaces may be repaired with any good asphalt patching compound available at most hardware and building supply centers. Concrete surfaces may be repaired with our #960 Concrete Patch or other material of like quality.

Once the surface repairs have been made and the patching material has set overnight, simply sweep the surface free of dirt and loose debris. No other surface preparation is necessary except on surfaces where grease, oil, or oily residue are present. These surfaces should be thoroughly washed with a solution of tri-sodium phosphate (TSP) or No. 910 Washing Compound. Mix the No. 910 Washing Compound or TSP at a ratio of 8 oz. of powder to 1 gallon of water. After scrubbing the surface thoroughly with this solution, hose down and rinse completely with water. To ensure better adhesion of the coating, new or non-porous, slick concrete surfaces should be etched with a 15% solution of muriatic acid before painting. After etching, scrub the surface thoroughly with TSP and water solution to neutralize any acid and then thoroughly rinse with fresh water.

Previously Painted Surfaces

DURACOURT will adhere to most other acrylic coatings; however, glossy paints should be sanded before applying DURACOURT. All peeling or flaking paint must be removed before painting.

Application Procedures

Step 1

Before applying Duracourt, mask the boundary lines with 2" masking tape. This will speed the coating process, as brushes will not be necessary to trim large areas

Step 2

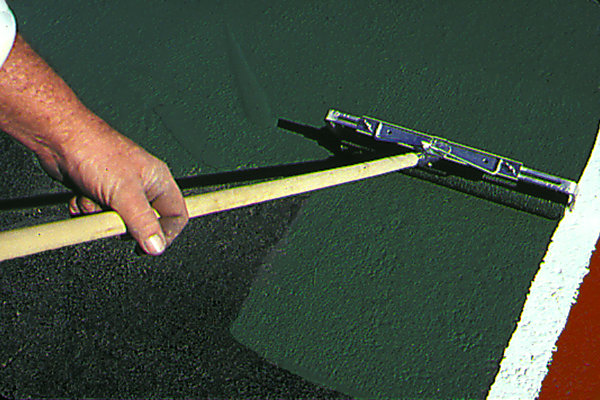

Coat the inbounds playing area first. We recommend using an 18" roller cover with a ½" nap. The roller frame should be equipped with a 4' – 5' extension handle to speed the coating process. Finish by coating the out-of-bounds area.

For greater ease of application, thin Duracourt coatings 10% with water. Stir thoroughly and pour out about ½ gallon onto the surface. Spread the coating liberally on the surface with the roller making sure not to spread it out too thin.

Material Needs

Use the spread rate of 125 sq ft per gallon to determine your material needs. A standard tennis court (60' x 120' overall dimension) will require 20-25 gallons to coat the inbounds area and 35-40 gallons for the out-of-bounds area. Pickleball court dimensions are 20' x 44' for the inbounds area and will require 8-9 gallons of coating. Use the spread rate to determine out-of-bounds coating needs for pickleball as it may vary. This is the same for basketball and volleyball courts as overall sizes will vary. Remember to account for the lines which are typically 2" wide with the baseline typically 4" wide. White is typically used for the lines but other colors are used – especially if adding a pickleball court to an existing tennis court